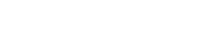

Raw Food Waste Recycling and Regeneration System

The initial development was initiated by the Environmental Protection Bureau's initiative to reduce the collection of kitchen waste on campus. Simultaneously, the school conducts food and agricultural courses that require fertilizers, necessitating additional expenditure. Hence, the Environmental Protection Bureau and the school jointly proposed the need for a solution.

Our company was approached for consultation, and together with Shan Chuan Machinery Factory Co., Ltd., we developed this system, which took a total of six months to complete. We successfully developed a processing equipment that meets the requirements of the school.

Our company was approached for consultation, and together with Shan Chuan Machinery Factory Co., Ltd., we developed this system, which took a total of six months to complete. We successfully developed a processing equipment that meets the requirements of the school.

- Company NameORIGINLIMIT CO., LTD.

This equipment is an enclosed kitchen waste processing system, roughly the size of a 20-foot shipping container. Due to its placement on campus, it is fully enclosed for safety reasons. The entire kitchen waste system can be operated by one person from feeding to discharging, and after production, it only needs to be placed in a container, sealed, and left to rest for 7 days before being incorporated into the soil. During the development process, planting tests were also conducted to experiment with various blending ratios to determine the appropriate planting ratio, which was then provided to customers for use.

1.No heating process, reducing energy consumption through the activation of microbial strains.

2.Modular equipment for safety and saving manpower operation time.

3.No water or air pollution.

4.Designed to the size of a 20-foot shipping container for easy modular export.

5.Equipped with an interactive human-machine interface, no additional installation required.

6.Processes an equivalent amount of kitchen waste with only 1/4 of the energy required compared to household kitchen waste machines.

7.SGS odor detection certified, no odor detected.

8.Simultaneously produces base fertilizer, which, upon testing, meets national organic composting standards 5-11.

1.No heating process, reducing energy consumption through the activation of microbial strains.

2.Modular equipment for safety and saving manpower operation time.

3.No water or air pollution.

4.Designed to the size of a 20-foot shipping container for easy modular export.

5.Equipped with an interactive human-machine interface, no additional installation required.

6.Processes an equivalent amount of kitchen waste with only 1/4 of the energy required compared to household kitchen waste machines.

7.SGS odor detection certified, no odor detected.

8.Simultaneously produces base fertilizer, which, upon testing, meets national organic composting standards 5-11.

__24E091l2TW.png)

__24F28dcE8S.png)

循環農業-1__24E17snjpA.jpg)