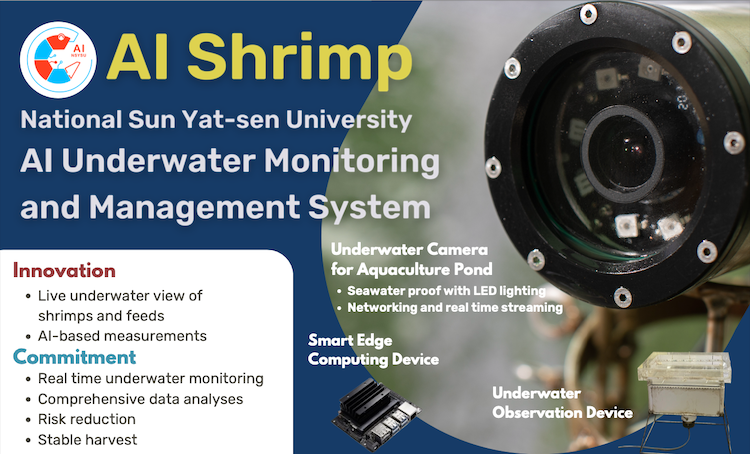

智慧電箱Smart Control Box

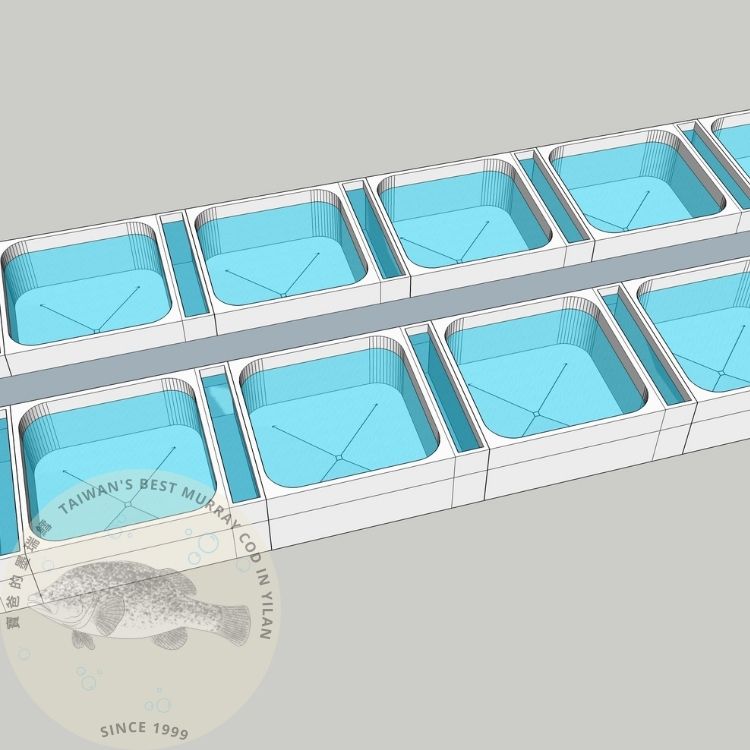

The "Smart Control Box" is an automated equipment designed specifically for traditional aquaculture. This product can transform traditional paddle wheels, blowers, inlet/outlet water systems and other equipment into automated control, realizing intelligent management of the aquaculture process. Through the smart control box, farmers can easily remotely monitor and control various equipment, thereby saving time and labor costs.

This smart control box can not only record the operating status and activity records of each device, but also issue alarms in real-time when equipment malfunctions, reminding users to carry out repairs, thereby reducing losses caused by equipment failures during the production process.

This product can be configured in aquaculture farms of various sizes, and the smart control box can provide effective solutions to help farmers achieve production automation and intelligent management, improving production efficiency and yield.

This smart control box can not only record the operating status and activity records of each device, but also issue alarms in real-time when equipment malfunctions, reminding users to carry out repairs, thereby reducing losses caused by equipment failures during the production process.

This product can be configured in aquaculture farms of various sizes, and the smart control box can provide effective solutions to help farmers achieve production automation and intelligent management, improving production efficiency and yield.

- Company NameID WATER CO., LTD.

■ Product Features

High-performance control

• Supports multiple control modes, including manual, stop and automatic, to meet different operation requirements.

• Equipped with VR knob and RS485 communication interface, providing flexible blower speed control.

Multiple protection mechanisms

• Equipped with overload lights to ensure timely warnings in case of overheating or short circuits, protecting equipment safety.

• Alarm system provides visual and audible alerts during faults, quickly notifying operators.

Easy operation

• Intuitive panel design with clearly marked buttons and indicator lights for easy operation.

• Simple selection of control modes for easy switching and operation.

Versatile applications

• Suitable for control and monitoring of blowers, paddle wheels, and sewage systems, adapting to various industrial application environments.

• Automatic control function of sewage electric valves enhances the operational convenience of sewage systems.

Reliable performance

• Equipment voltage is 3 Ø 220V, frequency is 60 HZ, and maximum current can reach 70 A, ensuring stable equipment operation.

• High-quality electrical components and circuit design ensure long-term stable operation.

Convenient maintenance

• Status indicator lights and overload lights enable faster fault diagnosis, saving maintenance time.

• Flexible control modes for sewage balls and sewage electric valves facilitate maintenance and adjustment.

High-performance control

• Supports multiple control modes, including manual, stop and automatic, to meet different operation requirements.

• Equipped with VR knob and RS485 communication interface, providing flexible blower speed control.

Multiple protection mechanisms

• Equipped with overload lights to ensure timely warnings in case of overheating or short circuits, protecting equipment safety.

• Alarm system provides visual and audible alerts during faults, quickly notifying operators.

Easy operation

• Intuitive panel design with clearly marked buttons and indicator lights for easy operation.

• Simple selection of control modes for easy switching and operation.

Versatile applications

• Suitable for control and monitoring of blowers, paddle wheels, and sewage systems, adapting to various industrial application environments.

• Automatic control function of sewage electric valves enhances the operational convenience of sewage systems.

Reliable performance

• Equipment voltage is 3 Ø 220V, frequency is 60 HZ, and maximum current can reach 70 A, ensuring stable equipment operation.

• High-quality electrical components and circuit design ensure long-term stable operation.

Convenient maintenance

• Status indicator lights and overload lights enable faster fault diagnosis, saving maintenance time.

• Flexible control modes for sewage balls and sewage electric valves facilitate maintenance and adjustment.

Design-0__24H30GxTli.png)