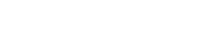

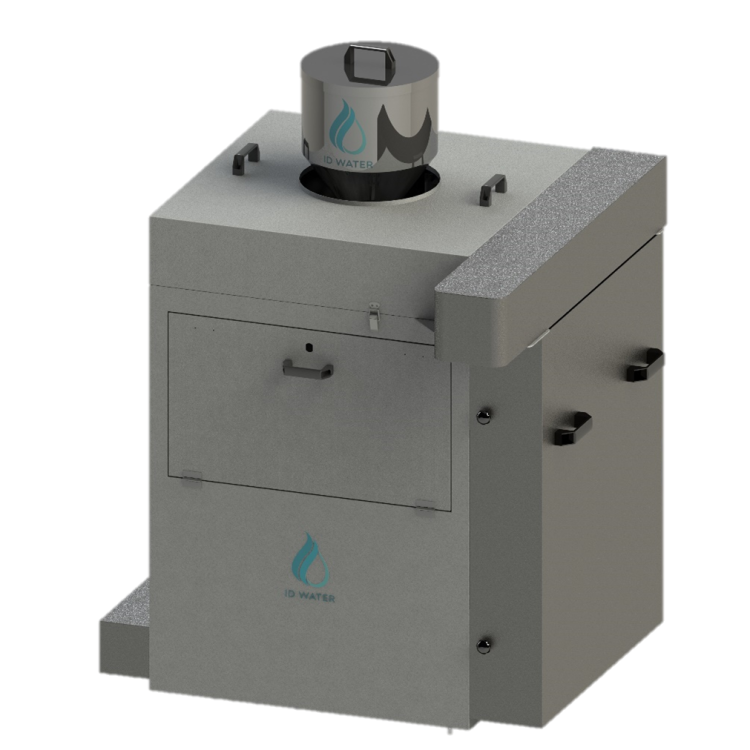

控制面板 Control Panel

The "Control Panel" is an innovative intelligent control system that integrates commonly used automation devices in aquaculture, such as feeders, water quality monitoring systems, and oxygenation equipment, into a convenient web-based user interface. Through this control interface, aquaculture personnel can easily perform remote control and real-time monitoring of the operating status and data of various devices using connected devices like smartphones and tablets.

Moreover, the control interface has intelligent functions that can automatically adjust the operating mode of the equipment based on preset parameters and conditions, thereby achieving automated management of the aquaculture process, greatly reducing labor requirements while improving production efficiency and quality.

Moreover, the control interface has intelligent functions that can automatically adjust the operating mode of the equipment based on preset parameters and conditions, thereby achieving automated management of the aquaculture process, greatly reducing labor requirements while improving production efficiency and quality.

- Company NameID WATER CO., LTD.

■ Product Features

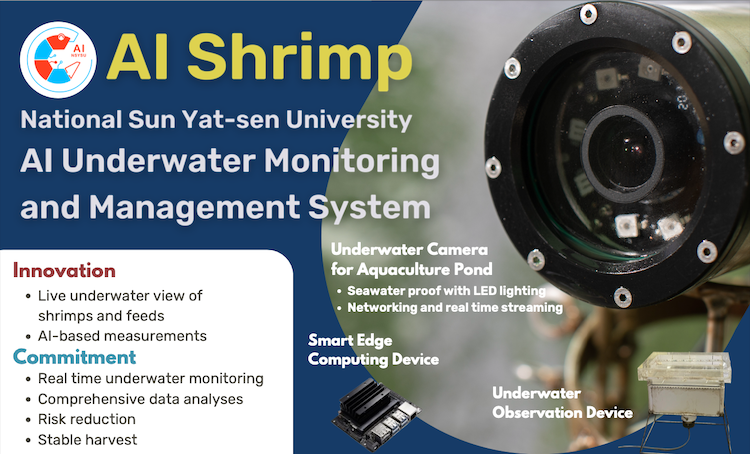

Intelligent Monitoring

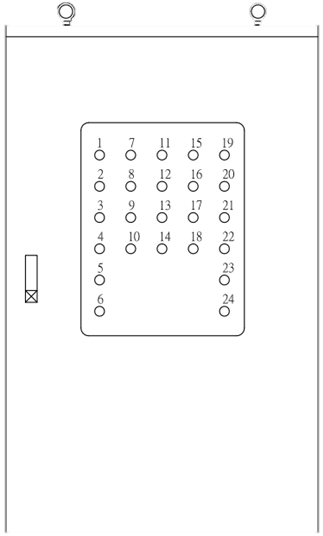

• Real-time data display: The system provides important environmental data such as water level percentage, dissolved oxygen value, water temperature, ammonia nitrogen, nitrite, pH value, and air tube pressure in the culture pond, helping farmers understand the pond conditions in a timely manner.

• 24-hour environmental data tracking: Real-time display of environmental changes within the last 24 hours, with color codes (green for normal, red for alert, gray for no data) to remind users to pay immediate attention to abnormal situations.

Automated Control

• Shell removal function: One-click activation of the shell removal function automatically raises the sewage ball, ensuring that the shrimp shells can be smoothly discharged, reducing manual operation.

• Inverter management: The system supports on/off control of the inverter, adjusting equipment operation according to actual needs, improving operational efficiency and energy-saving effects.

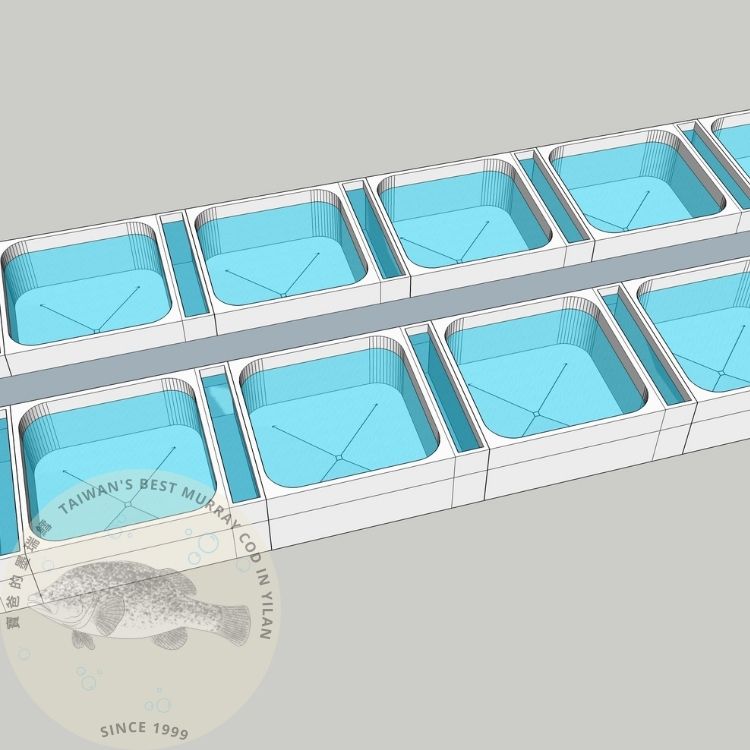

• Paddle wheel control: Supports on/off control of the paddle wheel, ensuring water circulation and maintaining stable water quality.

• Feeder management: Provides on/off control and feeding amount setting functions for two feeders, ensuring appropriate feed supply in the culture pond.

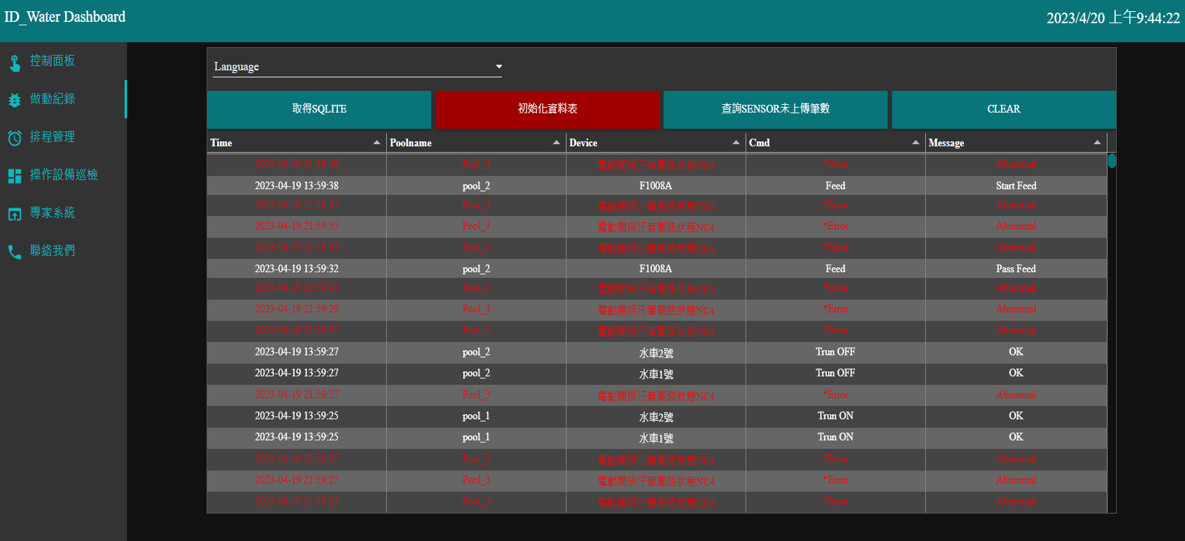

• Unified scheduling: The system supports unified scheduling settings for the entire farm, centrally managing the operating times of multiple devices, enhancing management efficiency.

• Single pond automation control: Based on individual pond settings, automatically triggers equipment operation, providing targeted management.

• Historical record retention: Saves the setting change records of each culture pond for easy query and traceability.

Intelligent Monitoring

• Real-time data display: The system provides important environmental data such as water level percentage, dissolved oxygen value, water temperature, ammonia nitrogen, nitrite, pH value, and air tube pressure in the culture pond, helping farmers understand the pond conditions in a timely manner.

• 24-hour environmental data tracking: Real-time display of environmental changes within the last 24 hours, with color codes (green for normal, red for alert, gray for no data) to remind users to pay immediate attention to abnormal situations.

Automated Control

• Shell removal function: One-click activation of the shell removal function automatically raises the sewage ball, ensuring that the shrimp shells can be smoothly discharged, reducing manual operation.

• Inverter management: The system supports on/off control of the inverter, adjusting equipment operation according to actual needs, improving operational efficiency and energy-saving effects.

• Paddle wheel control: Supports on/off control of the paddle wheel, ensuring water circulation and maintaining stable water quality.

• Feeder management: Provides on/off control and feeding amount setting functions for two feeders, ensuring appropriate feed supply in the culture pond.

• Unified scheduling: The system supports unified scheduling settings for the entire farm, centrally managing the operating times of multiple devices, enhancing management efficiency.

• Single pond automation control: Based on individual pond settings, automatically triggers equipment operation, providing targeted management.

• Historical record retention: Saves the setting change records of each culture pond for easy query and traceability.

Design-0__24H30GxTli.png)