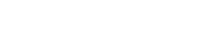

NIR-Online X-Sential™ | On-line analysis

All that is essential for process control.

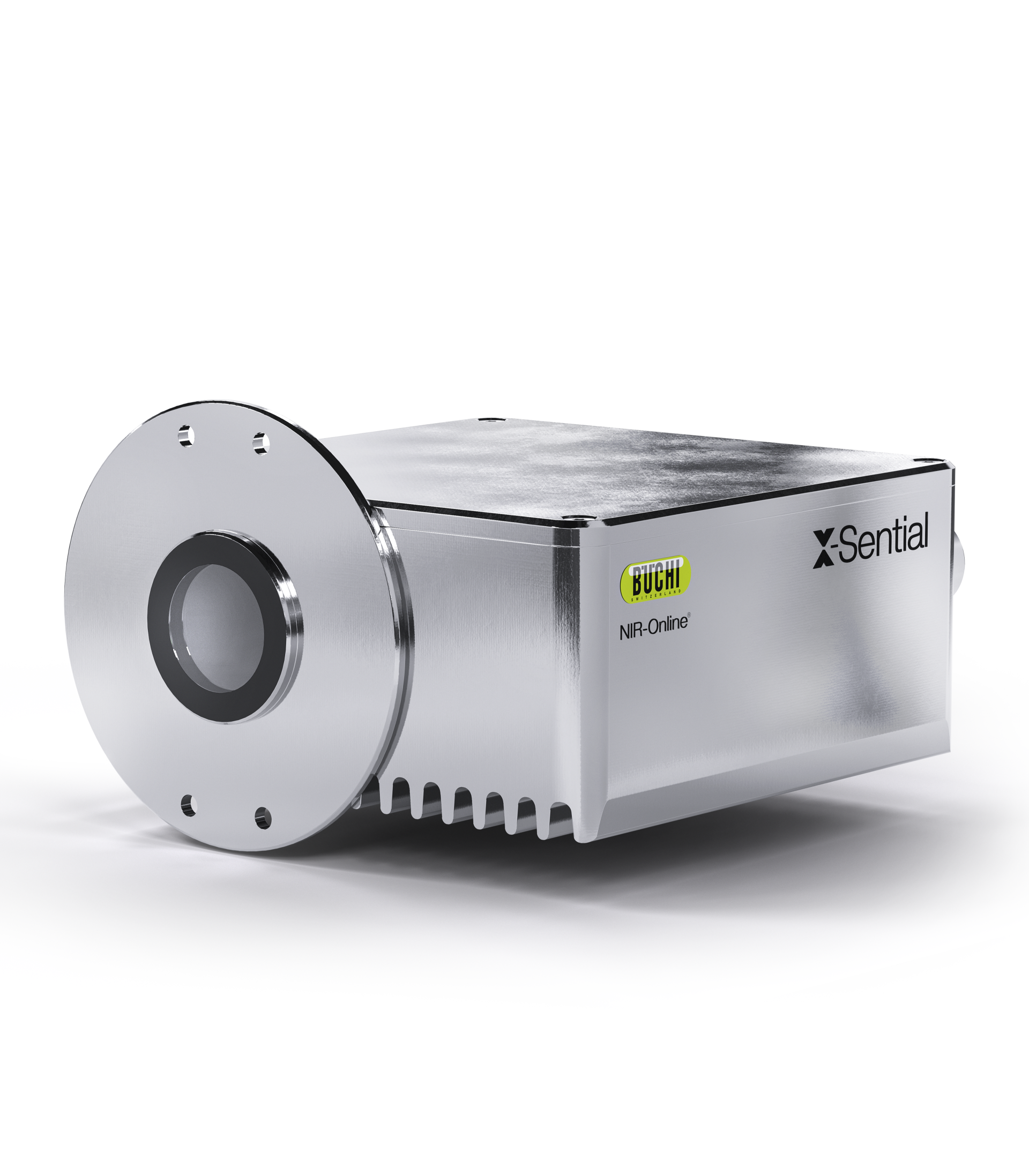

Closely monitoring basic parameters such as moisture, fat or protein is crucial to correct deviations in manufacturing processes. The X-Sential™ has been developed and designed as the most cost-efficient, fit-for-purpose process sensor.

Diode array technology:

High speed spectrometer

IP class:

Dust

NIR:

Wavelength range (900-1,700 nm)

Closely monitoring basic parameters such as moisture, fat or protein is crucial to correct deviations in manufacturing processes. The X-Sential™ has been developed and designed as the most cost-efficient, fit-for-purpose process sensor.

Diode array technology:

High speed spectrometer

IP class:

Dust

NIR:

Wavelength range (900-1,700 nm)

- Company NameBUCHI TAIWAN CO., LTD.

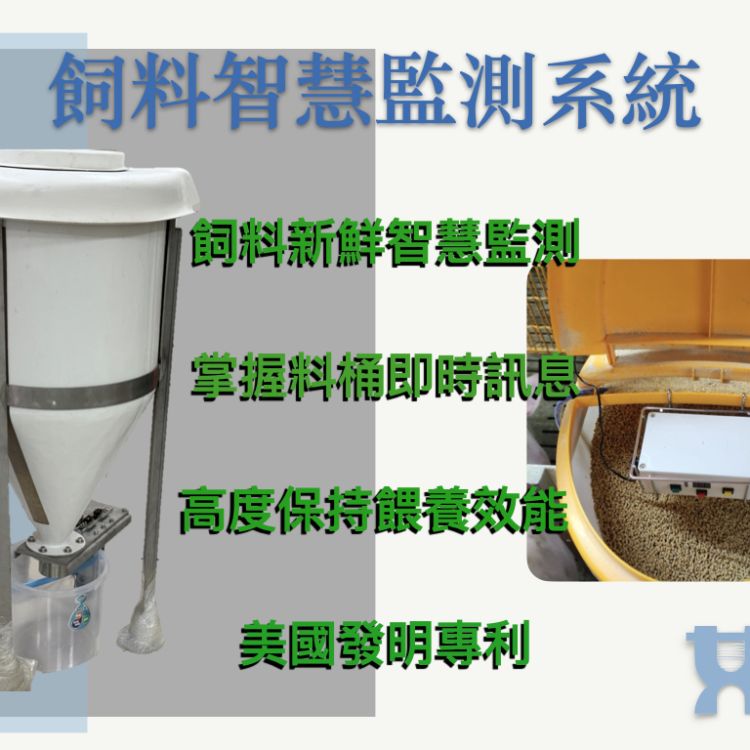

The BUCHI NIR-Online X-Sential is a high-performance near-infrared (NIR) spectrometer designed for industrial applications. It is primarily used for real-time chemical analysis during production processes without the need for sample preparation or destructive testing, significantly enhancing production efficiency and quality control.

The instrument utilizes advanced optical technology to quickly and accurately measure the chemical composition of various materials, such as moisture, protein, and fats. It is suitable for industries such as food and feed, chemicals, and pharmaceuticals, supporting a range of applications including raw material inspection, reaction monitoring, and finished product quality control.

With a user-friendly interface and powerful features, it enables real-time data visualization, remote monitoring, and data management, effectively increasing the transparency and control of production processes.

The instrument utilizes advanced optical technology to quickly and accurately measure the chemical composition of various materials, such as moisture, protein, and fats. It is suitable for industries such as food and feed, chemicals, and pharmaceuticals, supporting a range of applications including raw material inspection, reaction monitoring, and finished product quality control.

With a user-friendly interface and powerful features, it enables real-time data visualization, remote monitoring, and data management, effectively increasing the transparency and control of production processes.