KUKA robotic arm in the field of food industry automation

KUKA offers a wide range of industrial robot models with varying payload capacities and work envelopes. Our product line also includes compatible robot peripherals — from linear tracks to end effectors. Combined with advanced software and innovative control systems, we collaborate with you to develop customized solutions tailored to your production processes.

- Company NameKUKA AUTOMATION TAIWAN LTD.

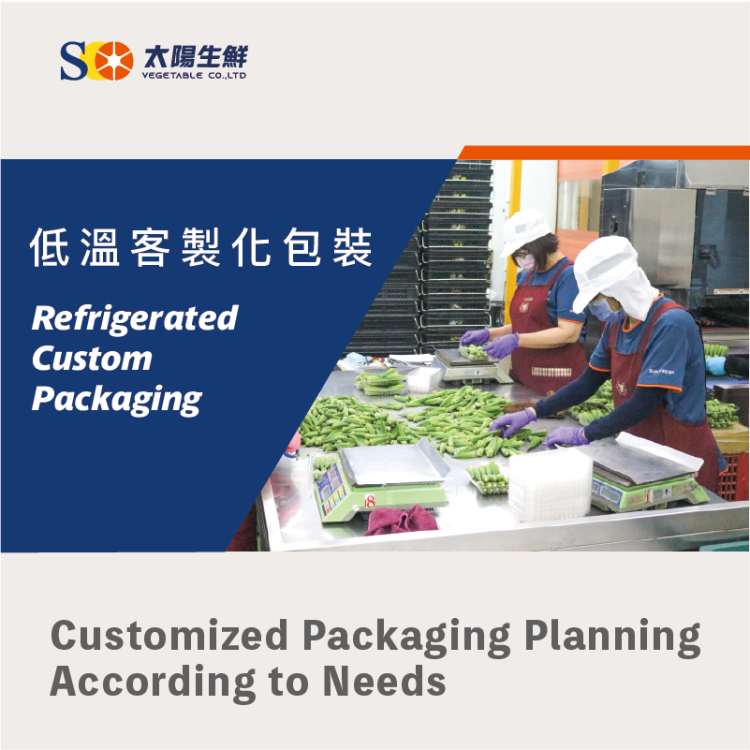

In the food industry, automation covers everything from raw material handling, food processing, packaging, stacking, to preparation for dispatch – all achievable with KUKA robots. Our comprehensive automation solutions enable you to efficiently manage applications within the food industry.

Our flexible and intelligent production lines are fully automated, applicable globally from transport to order picking and distribution. The process chain in the food industry typically begins with raw material handling, where KUKA starts and collaborates with Swisslog, a KUKA Group company, and other partners in logistics, warehouse, and distribution center operations. Additionally, KUKA automates nearly every step in the food industry, offering advantages such as increased productivity, reduced costs, and ensuring high-quality processes.

Our robot technologies are fast, compliant with hygiene standards, backed by deep expertise in the food industry, and supported by global customer service. KUKA's product range includes a variety of machines tailored for the modern food industry, meeting the highest hygiene standards and featuring specialized models for cold storage. All machine axes across all payload levels use lubricants suitable for food processing. We provide mobile platforms and suitable software for critical process steps such as handling, picking, or stacking tasks.

Our flexible and intelligent production lines are fully automated, applicable globally from transport to order picking and distribution. The process chain in the food industry typically begins with raw material handling, where KUKA starts and collaborates with Swisslog, a KUKA Group company, and other partners in logistics, warehouse, and distribution center operations. Additionally, KUKA automates nearly every step in the food industry, offering advantages such as increased productivity, reduced costs, and ensuring high-quality processes.

Our robot technologies are fast, compliant with hygiene standards, backed by deep expertise in the food industry, and supported by global customer service. KUKA's product range includes a variety of machines tailored for the modern food industry, meeting the highest hygiene standards and featuring specialized models for cold storage. All machine axes across all payload levels use lubricants suitable for food processing. We provide mobile platforms and suitable software for critical process steps such as handling, picking, or stacking tasks.

__24F14UgMVz.jpeg)