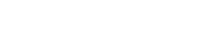

TITAN ARK Intelligent Environmental Control System for Livestock and Poultry Housing

TITAN ARK is a climate control system specifically developed for livestock and poultry housing in subtropical climates. It allows you to customize your livestock and poultry housing environment using the most advanced cloud-based intelligent control system tailored to your specific needs. It is perfectly integrated for all new or existing facilities, including natural, mechanical, and combination ventilation such as side windows, positive pressure, negative pressure, and ventilation systems. The system can control fans, exhaust, heating, heat exchangers, negative pressure water curtain cooling, canvas roller blinds, misting, emergency opening, and alarms.

TITAN ARK Intelligent Environmental Control System for Livestock and Poultry Housing

TITAN ARK is not just an intelligent control system for livestock and poultry housing, but also features highly efficient real-time cloud functions. It records all essential environmental data, allowing you to monitor them in real-time and receive alerts when changes occur. No matter where you are, you can take necessary actions quickly to improve conditions, ensuring a better biosecurity environment and increased production efficiency.

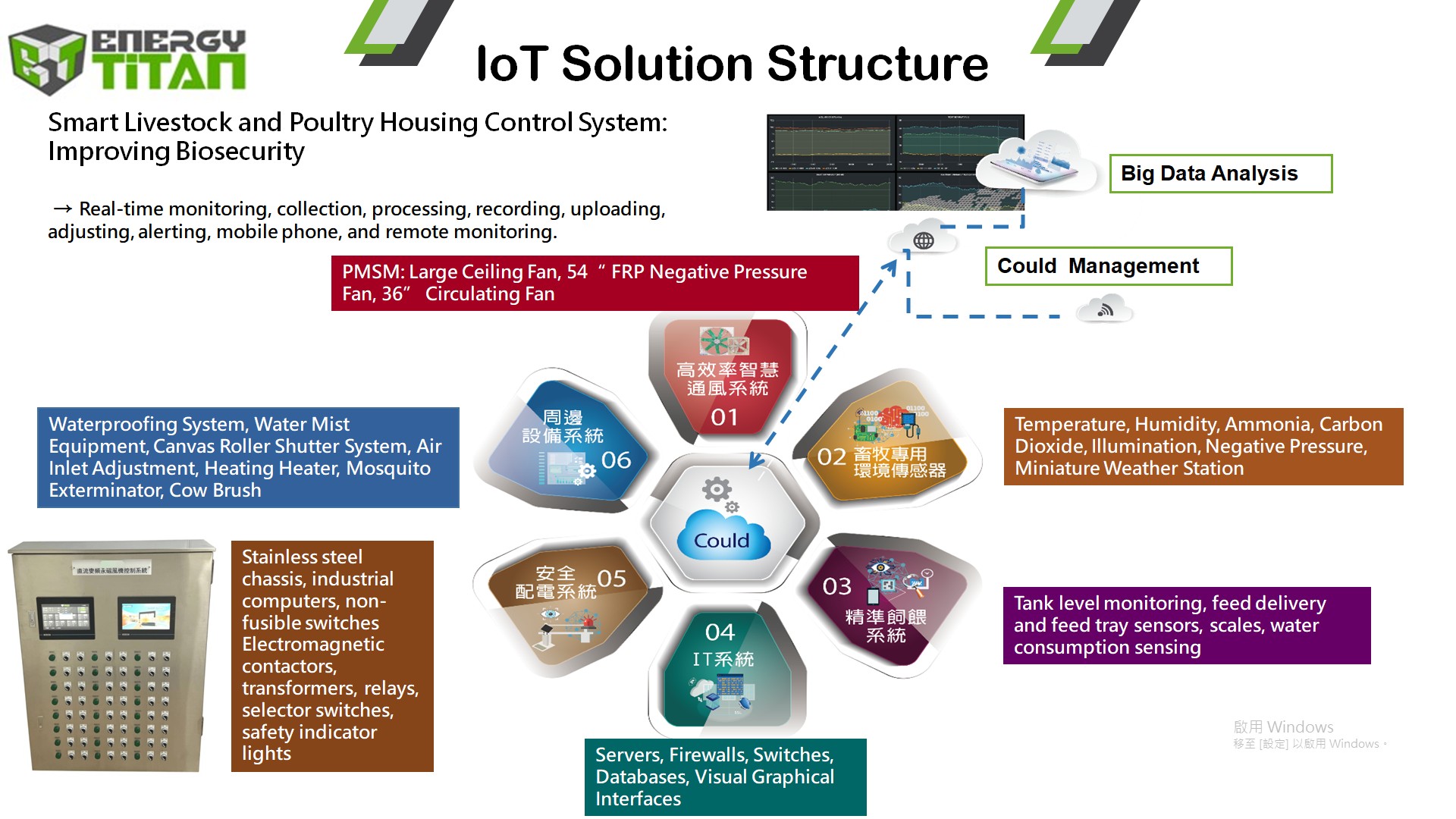

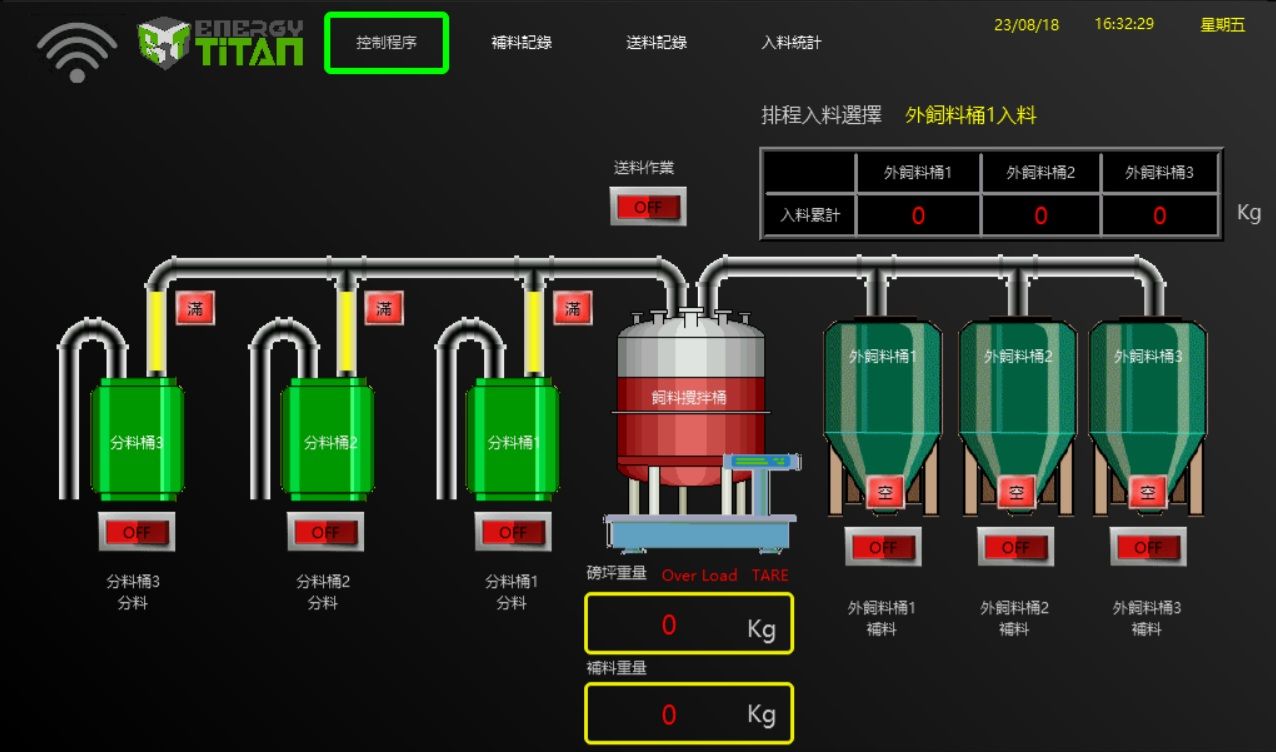

TITAN ARK Intelligent Feed/Water System

Developed for Taiwan's livestock and poultry feed delivery systems, it can be fully automatically controlled or semi-controlled with the native system, allowing you to determine the most suitable method based on your configuration and needs. It integrates user feed, mixing tanks, scales, and digital sensors at each feeding station to detect feeding time, weight, and zone feeding statistics. According to user needs and requirements, different automatic control feeding, mixing options, and statistics can be programmed. It precisely records the feeding amount and values at each feeding station, providing complete reports corresponding to growth and mixing curves.

TITAN ARK Intelligent Lighting Control System

The system can be scheduled and record light intensity (lux) and opening/closing time curves for owners to compare production value trends to improve output. Efficient and energy-saving, with multiple protections, the duration, intensity, and wavelength of light will affect the reproductive traits, physiological traits, milk yield, meat yield, egg production rate, and egg cholesterol content of livestock and poultry. Therefore, it provides appropriate light intensity (Lux) and time plans according to the different growth stages of livestock and poultry and can automatically adjust based on seasonal sunset times.

TITAN ARK Intelligent Environmental Control System for Livestock and Poultry Housing

TITAN ARK is not just an intelligent control system for livestock and poultry housing, but also features highly efficient real-time cloud functions. It records all essential environmental data, allowing you to monitor them in real-time and receive alerts when changes occur. No matter where you are, you can take necessary actions quickly to improve conditions, ensuring a better biosecurity environment and increased production efficiency.

TITAN ARK Intelligent Feed/Water System

Developed for Taiwan's livestock and poultry feed delivery systems, it can be fully automatically controlled or semi-controlled with the native system, allowing you to determine the most suitable method based on your configuration and needs. It integrates user feed, mixing tanks, scales, and digital sensors at each feeding station to detect feeding time, weight, and zone feeding statistics. According to user needs and requirements, different automatic control feeding, mixing options, and statistics can be programmed. It precisely records the feeding amount and values at each feeding station, providing complete reports corresponding to growth and mixing curves.

TITAN ARK Intelligent Lighting Control System

The system can be scheduled and record light intensity (lux) and opening/closing time curves for owners to compare production value trends to improve output. Efficient and energy-saving, with multiple protections, the duration, intensity, and wavelength of light will affect the reproductive traits, physiological traits, milk yield, meat yield, egg production rate, and egg cholesterol content of livestock and poultry. Therefore, it provides appropriate light intensity (Lux) and time plans according to the different growth stages of livestock and poultry and can automatically adjust based on seasonal sunset times.

- Company NameENERGY TITAN CO .,LTD.

Cloud Livestock Data Management Function:

Real-time environmental information and data of livestock housing, including temperature, humidity, ammonia, and carbon dioxide levels, can be monitored in real-time. Managers can view the livestock housing environment information through mobile devices (Android, iOS) or personal computer web browsers.

Real-Time Data Analysis Function:

Managers can cross-reference data of livestock housing to identify potential causes of feeding differences. Each chart can be used for overlay cross-analysis of environmental factors such as ammonia, carbon dioxide, temperature, and humidity, along with breeding records parameters such as growth rate, daily feed intake, and daily weight gain.

Intelligent Livestock Housing Control Function:

Utilizing the values transmitted to the network by sensor hosts, the system can activate or deactivate various equipment switches in the livestock housing, such as fans, water curtains, heaters, misters, and side windows. Each building within the livestock housing requires a set of controllers, calculated per building.

Real-Time Alert Notification Function:

Managers can bind their LINE accounts and enable field notification functions for information such as rapid temperature changes, high temperature, low temperature, high ammonia concentration, and high carbon dioxide concentration. Managers can also directly change the farm's alert threshold settings through the cloud, such as raising the high-temperature alert from 30ºC to 35ºC.

Real-time environmental information and data of livestock housing, including temperature, humidity, ammonia, and carbon dioxide levels, can be monitored in real-time. Managers can view the livestock housing environment information through mobile devices (Android, iOS) or personal computer web browsers.

Real-Time Data Analysis Function:

Managers can cross-reference data of livestock housing to identify potential causes of feeding differences. Each chart can be used for overlay cross-analysis of environmental factors such as ammonia, carbon dioxide, temperature, and humidity, along with breeding records parameters such as growth rate, daily feed intake, and daily weight gain.

Intelligent Livestock Housing Control Function:

Utilizing the values transmitted to the network by sensor hosts, the system can activate or deactivate various equipment switches in the livestock housing, such as fans, water curtains, heaters, misters, and side windows. Each building within the livestock housing requires a set of controllers, calculated per building.

Real-Time Alert Notification Function:

Managers can bind their LINE accounts and enable field notification functions for information such as rapid temperature changes, high temperature, low temperature, high ammonia concentration, and high carbon dioxide concentration. Managers can also directly change the farm's alert threshold settings through the cloud, such as raising the high-temperature alert from 30ºC to 35ºC.