LAIDIG SYSTEMS, INC.

- Booth No.Online Show

- Websitehttps://www.laidig.com/

Company Profile

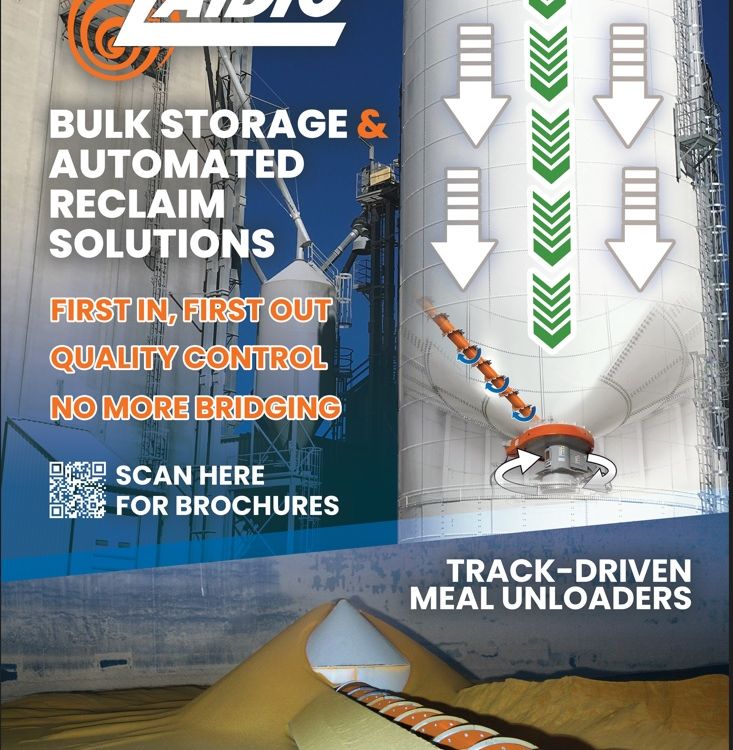

Laidig is proud to be the world leader in bulk storage and reclaim systems.

Our systems offer proven performance and reliability that is second-to-none. We are recognized around the globe for our custom-engineered, customer-first approach in everything we do. Ever since our company's inception in 1961, we've worked hard to solve unprecedented material handling problems across the countless industries we serve, including food processing, meals, pulp & paper, wood pelleting, biomass, power, biofuels, ethanol, mining & minerals, cement, and so many more.

Laidig specializes in customized, aggressive, screw-type bottom reclaimers designed to start and operate under a full material load. The screw rotates about its own axis, pulling material toward the center of the silo floor. At the same time, the screw slowly advances forward, sweeping around the entire silo floor. As material is augered to the center of the silo floor, it flows down through a center chute below the floor and into a discharge auger or conveyor for transfer out of the silo and to the next step in the material handling process.

Our equipment reduces and eliminates silo bridging and rat-holing, helps create mass flow, decreases the potential for product infestation, and maintains a first-in, first-out (FIFO) material distribution pattern, ensuring material quality and uninterrupted facility operations.

Our systems offer proven performance and reliability that is second-to-none. We are recognized around the globe for our custom-engineered, customer-first approach in everything we do. Ever since our company's inception in 1961, we've worked hard to solve unprecedented material handling problems across the countless industries we serve, including food processing, meals, pulp & paper, wood pelleting, biomass, power, biofuels, ethanol, mining & minerals, cement, and so many more.

Laidig specializes in customized, aggressive, screw-type bottom reclaimers designed to start and operate under a full material load. The screw rotates about its own axis, pulling material toward the center of the silo floor. At the same time, the screw slowly advances forward, sweeping around the entire silo floor. As material is augered to the center of the silo floor, it flows down through a center chute below the floor and into a discharge auger or conveyor for transfer out of the silo and to the next step in the material handling process.

Our equipment reduces and eliminates silo bridging and rat-holing, helps create mass flow, decreases the potential for product infestation, and maintains a first-in, first-out (FIFO) material distribution pattern, ensuring material quality and uninterrupted facility operations.